Snack

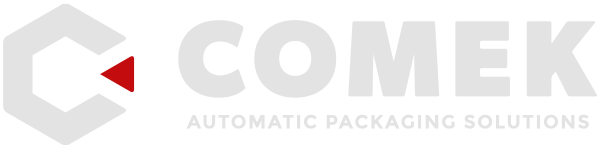

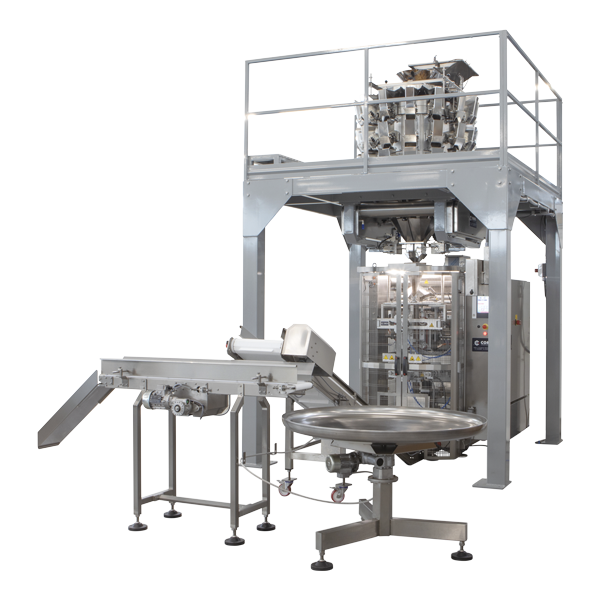

These are the main characteristics of a snack packaging line. Oil, salt, aromas and crumbs presence requires the construction of the machines in AISI 304 or AISI 316 stainless steel to ensure efficient maintenance over time and ensure cleaning.

-

chips, corn extruded, popcorn etc.

chips, corn extruded, popcorn etc.

-

dried fruits & nuts (peanuts, almonds, pistachios, etc.)

dried fruits & nuts (peanuts, almonds, pistachios, etc.)

-

crackers, breadsticks, taralli, pretzels etc.

crackers, breadsticks, taralli, pretzels etc.

Ecopackaging: the future

of packaging

The energy efficiency of the machine is guaranteed by the construction according to the EU regulation 2019/1781, through motors connected to inverters, in accordance with IEC 60034-30 standard on the efficiency classes of AC motors with mains power supply.

Paper film

Compostable materials

100% recyclable

Weighers

M version.

DP version.

DP-2 version.

The components in contact with the products are made of AISI 304 or AISI 316 stainless steel with plain or rigidized sheets to improve product flow.

Chutes and lower cone, of particular shape and inclination to speed up the fall of the product.

Special HS timing hopper with independent double opening specially designed to increase weighing speed.

Automatic distribution systems to interface the weighers with thermosealing, thermoforming machines or special filling lines.

Vertical packaging machines

PACKAGING MACHINE OMNYA EVO

Triple mode of operation: continuous, intermittent and Doypack.

Realization of pillow bags, block bottom bags, block bottom with four seals, doy-pack.

PACKAGING MACHINE VPB EVO

Mode of operation: intermittent.

Realization of pillow bags, block bottom bags, block bottom with four seals.

Mode of operation: intermittent.

Realization of pillow bags, block bottom bags.

Mode of operation: intermittent.

Realization of pillow bags.

SPECIAL DEVICES

Anti-obstruction systems entering the forming tube and settling the product in the package prevent production stops.

Technology MAP – Modified Atmosphere Packaging

A particularly effective way to extend the lifetime of products. Digital flowmeter with gas input times can be set from the display.

Robot di inserimento gadget nelle confezioni sistemi automatici per inserimento strisce pubblicitarie

Automatic film reel change system

To avoid time loss.

Horizontal packaging machine

AISI 304 stainless steel cantilevered frame for maximum hygiene and ease of cleaning.

LD horizontal sealing group to ensure hermetic packaging.

Denester trays from 1 to 4 rows with quick and easy format change.

Filling, closing and capping machines