Confectionary

These are the qualities needed for successful packaging plants for the confectionary industry. This sector includes a wide range of products with different characteristics, from sticky and sugary, to delicate and fragile.

We use special solutions for machine parts in contact with the product to manage them easily and effectively.

-

Oily naked, sugary nude, gelee candies etc.

Oily naked, sugary nude, gelee candies etc.

-

Fragile and not-fragile biscuits etc.

Fragile and not-fragile biscuits etc.

-

Chocolates, pralines, sugared almonds, chocolate chips etc.

Chocolates, pralines, sugared almonds, chocolate chips etc.

-

Cocoa powder, prepared for ice cream, cream etc.

Cocoa powder, prepared for ice cream, cream etc.

Ecopackaging: the future

of packaging

The energy efficiency of the machine is guaranteed by the construction according to the EU regulation 2019/1781, through motors connected to inverters, in accordance with IEC 60034-30 standard on the efficiency classes of AC motors with mains power supply.

Paper film

Compostable materials

100% recyclable

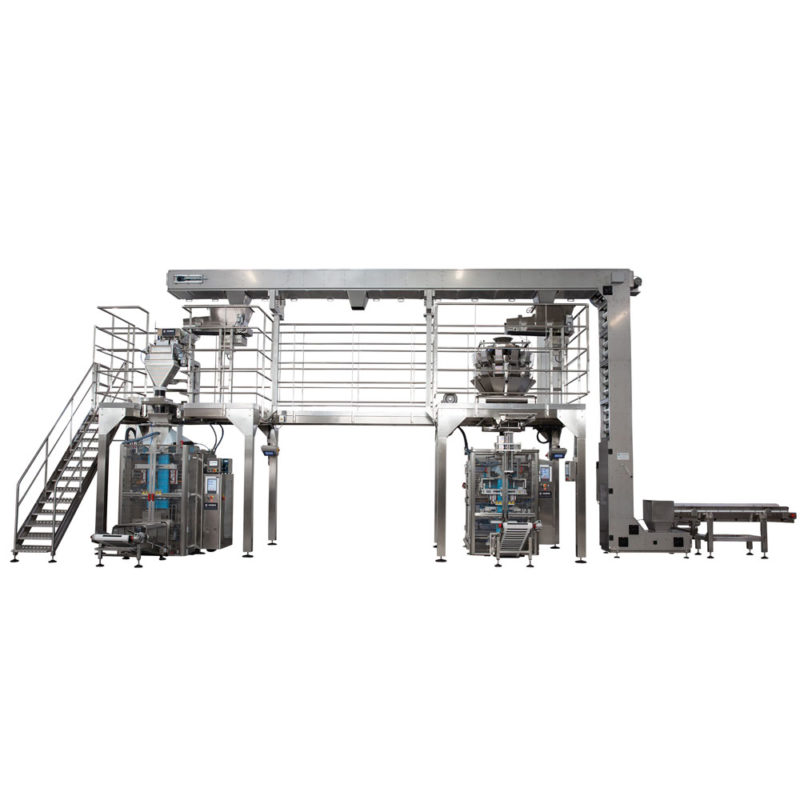

Weighers

DP version.

Mix version.

Custom version.

The components in contact with the products are made of AISI 304 stainless steel with special rigidized sheets to improve product flow.

Food grade silicone detectable rubber coating of parts in contact with product to safeguard its integrity.

Intermediate brake-stop to safeguard product integrity

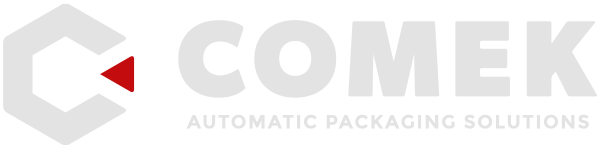

Vertical packaging machines

PACKAGING MACHINE OMNYA EVO

Triple mode of operation: continuous, intermittent and Doypack.

Realization of pillow bags, block bottom bags, block bottom with four seals, doy-pack.

PACKAGING MACHINE VPB EVO

Mode of operation: intermittent.

Realization of pillow bags, block bottom bags, block bottom with four seals.

Mode of operation: intermittent.

Realization of pillow bags, block bottom bags.

“SOLID BAG” technology

For visually perfect packaging.

Technology MAP – Modified Atmosphere Packaging

A particularly effective way to extend the lifetime of products. Digital flowmeter with gas input times can be set from the display.

Possibility to apply clip or twist in automatic

Hot cutting to obtain Eurohole or handles that do not weaken the hermetically sealed of the package.

Horizontal packaging machine

AISI 304 stainless steel cantilevered frame for maximum hygiene and ease of cleaning.

LD horizontal sealing group to ensure hermetic packaging.

Denester trays from 1 to 4 rows with quick and easy format change.

Filling, closing and capping machines