Safeguarding the integrity and hygiene of the product are the most important requirements when it comes to packaging dairy products.

For mozzarella, in particular, it is essential to effectively manage the moisture and sticky consistency of the product, without forgetting the need to ensure perfect airtightness of the packaging.

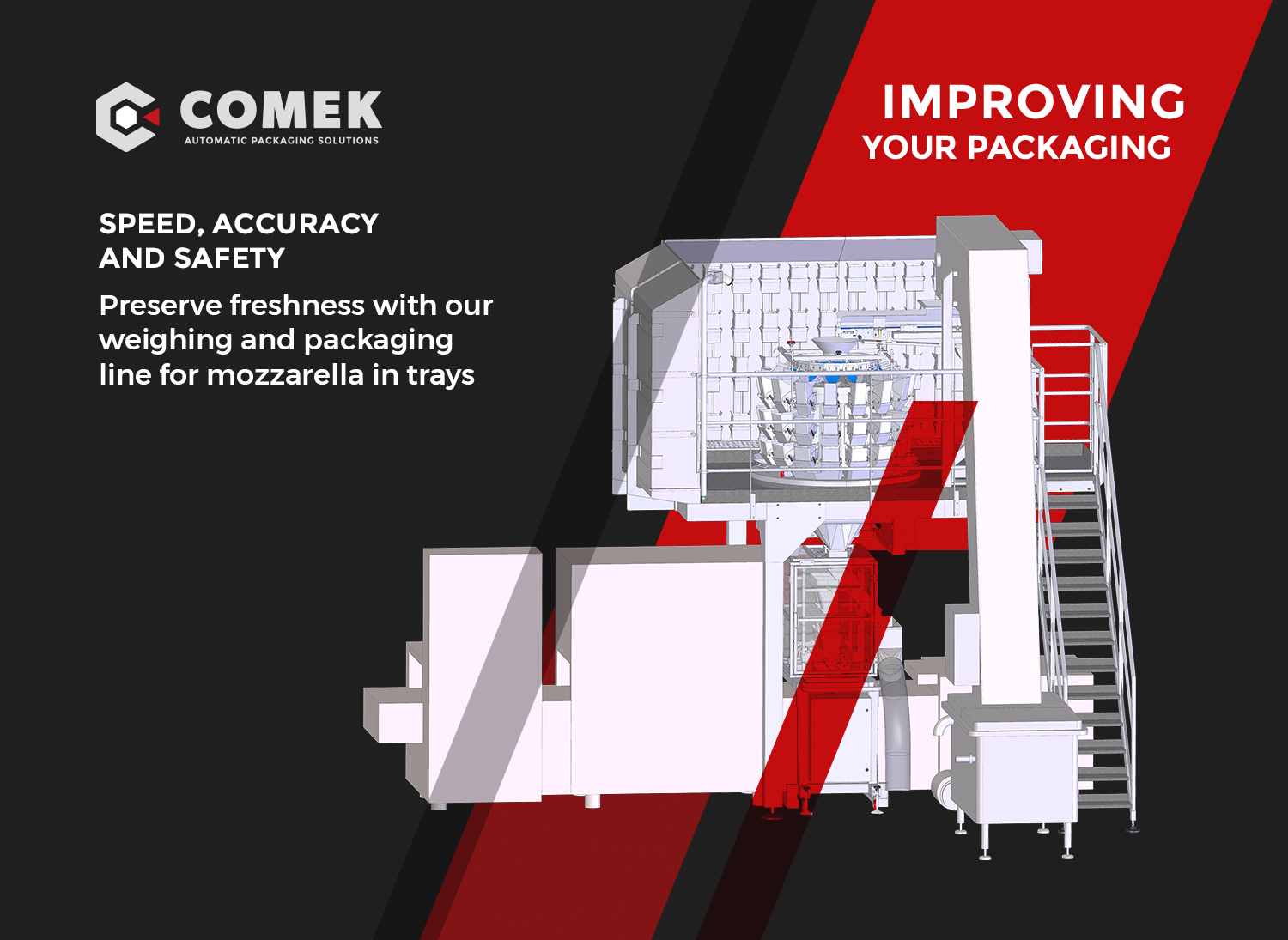

This is why, thanks to the virtuous collaboration with Inox CMP and AMC Packaging, we have designed a complete weighing and packaging line for mozzarella in trays, developed for a major company specializing in the production of buffalo mozzarella.

Speed, accuracy and safety

A durable and reliable system over time, which emphasizes speed and precision in weighing.

Our line guarantees a speed of 110/120 weighings per minute, which can be packaged in preformed round trays of 150/250g.

Among the components of the system made by Comek, we find:

- A 16-head multihead weigher CK16ST-DP-2, completely made of AISI 304 stainless steel for maximum hygiene;

- A stainless steel AISI 304 platform for supporting the weigher;

- A stainless steel wall for washing the weigher’s buckets;

- A stainless steel wall for washing the vibrating channels of the multihead weigher;

- A connecting conveyor belt;

- A special execution elevator belt, prepared for automatic CIP (Clean In Place) washing, designed to offer deep and continuous cleaning of the parts in contact with the product;

- A router for remote assistance.

Technologies at the Service of Hygiene

We have paid the utmost attention to protecting mozzarella from any type of contamination.

All parts in contact with the product are made of AISI 304 stainless steel sheet, universally recognized for its hygienic properties when in contact with food.

The washing walls, fixed on the upper part of the platform, also facilitate and speed up cleaning procedures.

Discover all the solutions we have designed for the Dairy sector.