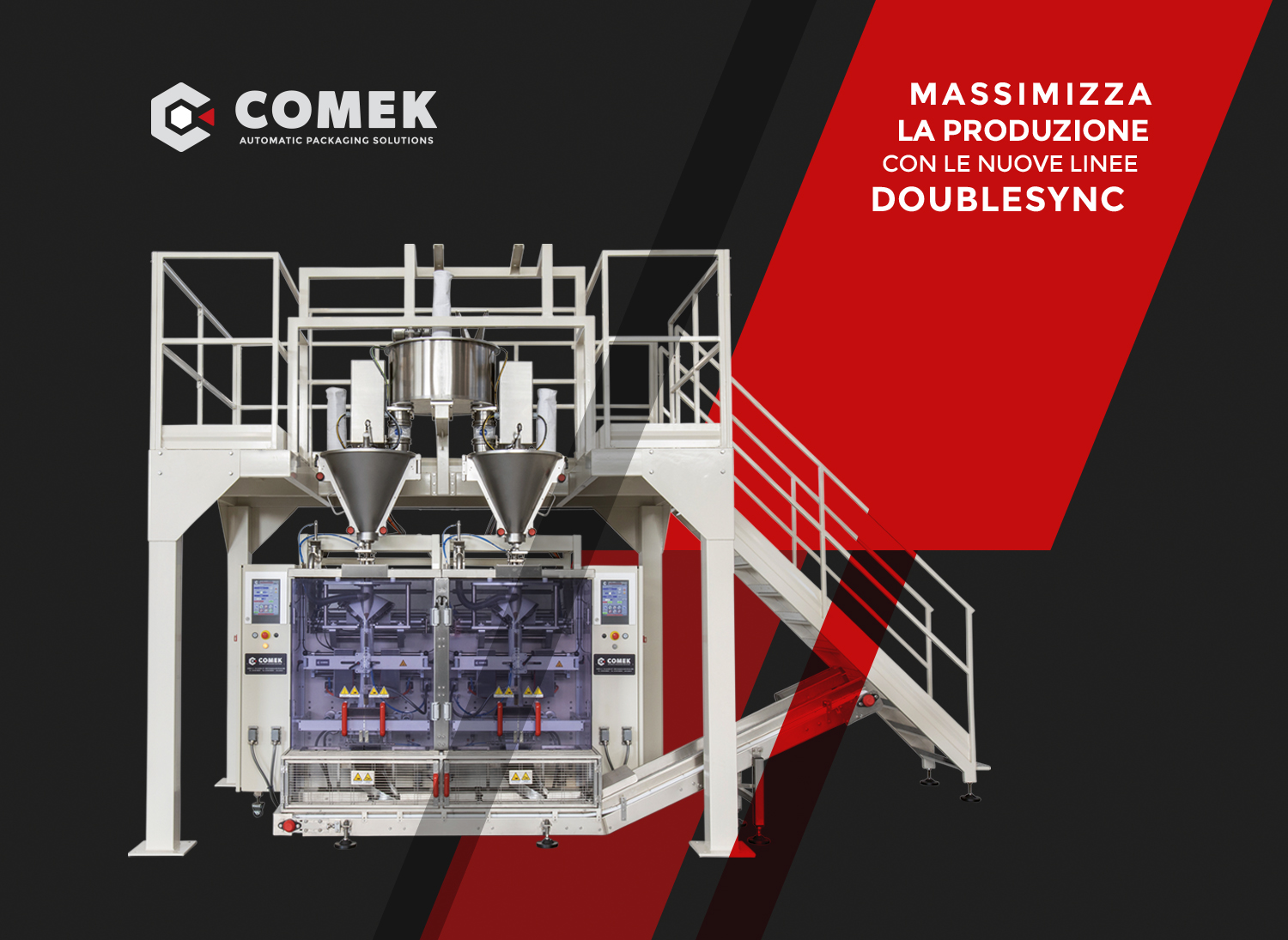

Reliability and accuracy in less space, thanks to our new compact solution with 2 systems in parallel.

The “DoubleSync” line consists of 2 Comek VPE vertical packaging machines and 2 vertical auger dosers, perfect for dosing and packaging dusty products such as coffee, cocoa and puree mixes.

The careful studies in the design phase progress and the special configurations of the machines avoid dispersing the product in the environment, reducing waste and preserving cleanliness in the work area.

A management software developed ad hoc guarantees perfect synchronism between the packaging machines and the conveyor belt. Thanks to this technology, the outgoing bags will always maintain the right distance, even with only one active packaging machine, avoiding overlapping and delays to the machine at the end of the line.

The parallel configuration allows to double the production: the new “DoubleSync” reach up to 90 pillow and square bottom bags per minute, from 50 g up to 250 g.

Our new solution is also ideal in cases where you need to make the most of the little space available. The compact configuration guarantees an exceptional optimization of the

dimensions and is easily manageable by a single operator.

The “DoubleSync” line allows you to use eco-sustainable films, made of monomaterial, compostable or recyclable paper, while maintaining the same level of performance in terms

of sturdiness and hermeticity of the packages.

Safety is our top priority right from the design stage. “DoubleSync” lines can be manufactured in compliance with the ATEX zone 22 standard, which certifies a safe, reliable work environment that is not susceptible to transforming into an explosive atmosphere in the form of a dust cloud.