Filling, closing and capping machines

The shapes of containers are extremely varied, according to the requirements of the customer, the product and the market.

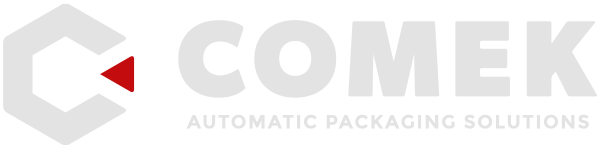

CBR

Rotary step machine with reduced dimensions and productive capacity up to 4,500 pieces/hour. Suitable for stackable plastic or laminated paper containers.

Matching with multihead weighers, linear weighers, auger dosers for powder products, pneumatic dosers for liquids, and cup dosers for granular products.

- Automatic denesting containers.

- Product dosing area.

- Thermosealing with film from reel, and tab for easy opening. Alternatively, thermosealing with pre-cut aluminium layer.

- Automatic capping containers, with stackable and non-stackable caps.

LRB

Rotary step machine with reduced dimensions and production capacity up to 3.000 pieces/hour. Suitable for plastic, laminated paper, tinplate or non-stackable glass containers.

Matching with multihead weighers, linear weighers, auger dosers for powder products, pneumatic dosers for liquids, and cup dosers for granular products.

- Input auger in order to space and to phase the containers.

- Input star, positioning star for container filling and exit star are in continuous motion and controlled by one motor.

- Product dosing area.

- Rapid format change.

CAP

Linear step machine for high productivity up to 19,000 pieces/hour. Suitable for stackable plastic or laminated paper containers.

“Custom” version with special shaped container cups make the machine able to produce more varied and irregular shapes without changing format.

Matching with multihead weighers, linear weighers, piece counting device, auger dosers for powder products, pneumatic dosers for liquids, and cup dosers for granular products.

- Automatic denesting containers.

- Product dosing area.

- Thermosealing with film from reel, and tab for easy opening. Alternatively, thermosealing with pre-cut aluminium layer.

- Automatic capping containers, with stackable and non-stackable caps.

- Exit Pick&Place in order to put products directly into display cases or boxes.

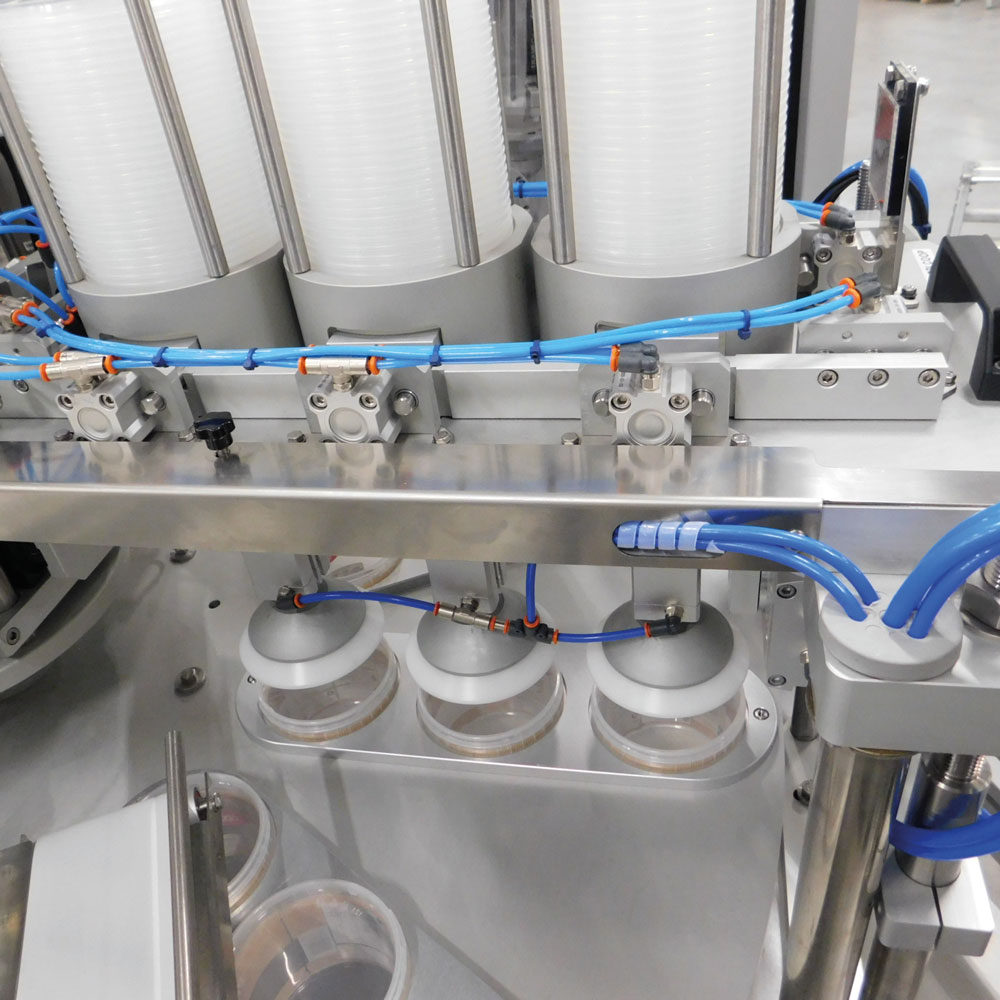

SEMI-AUTOMATIC AND AUTOMATIC LINES

Lines developed with in-line transport systems for plastic and laminated paper containers, glass jars of various shapes, stackable and non-stackable. Modular lines that can be created with only some automatic stations with the possibility to implement the rest at later times depending on the development of the production.

Matching with multihead weighers, linear weighers, auger dosers for powder products, pneumatic dosers for liquids, and cup dosers for granular products.

- Rotating table to stock incoming containers, or automatic denesting station.

- Transport system with conveyor belt or push rods.

- Product dosing area.

- Thermosealing with film from reel and tab for easy opening. Alternatively, thermosealing with pre-cut aluminium layer.

- Area for manual or automatic capping, with stackable and non-stackable caps.

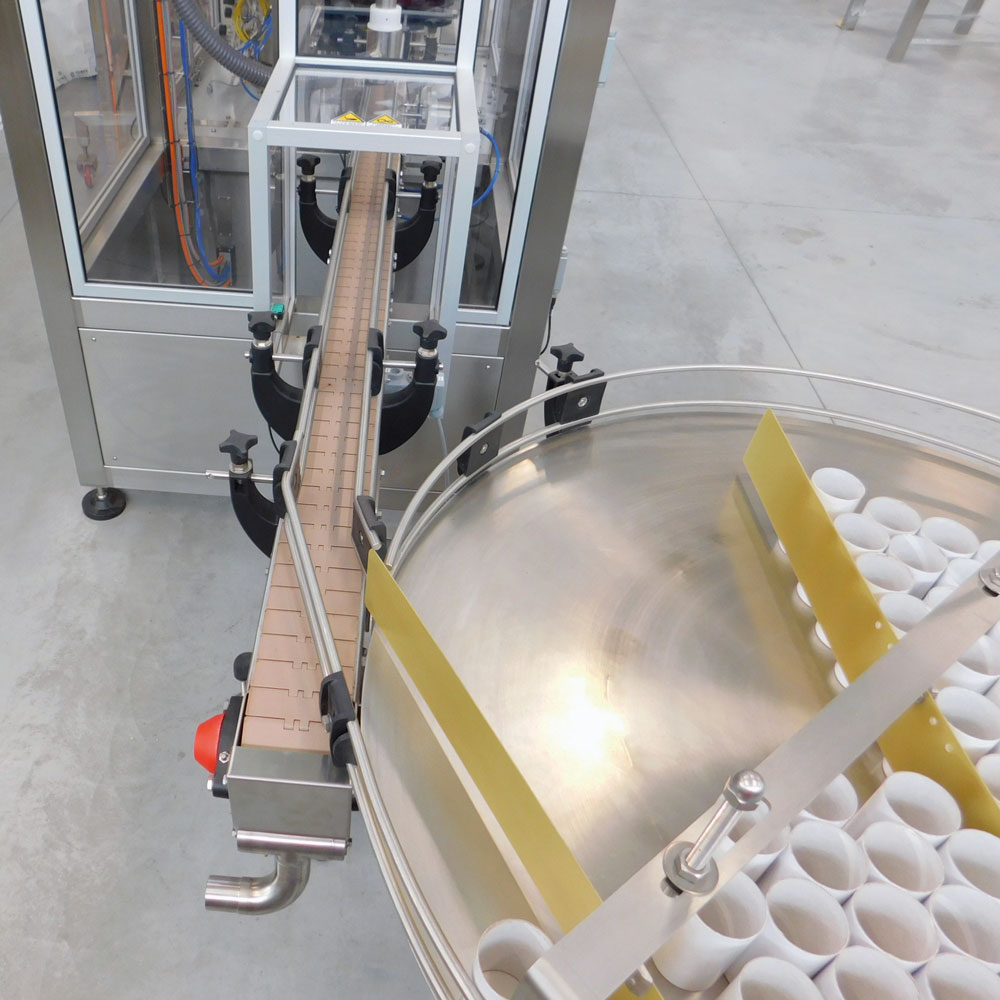

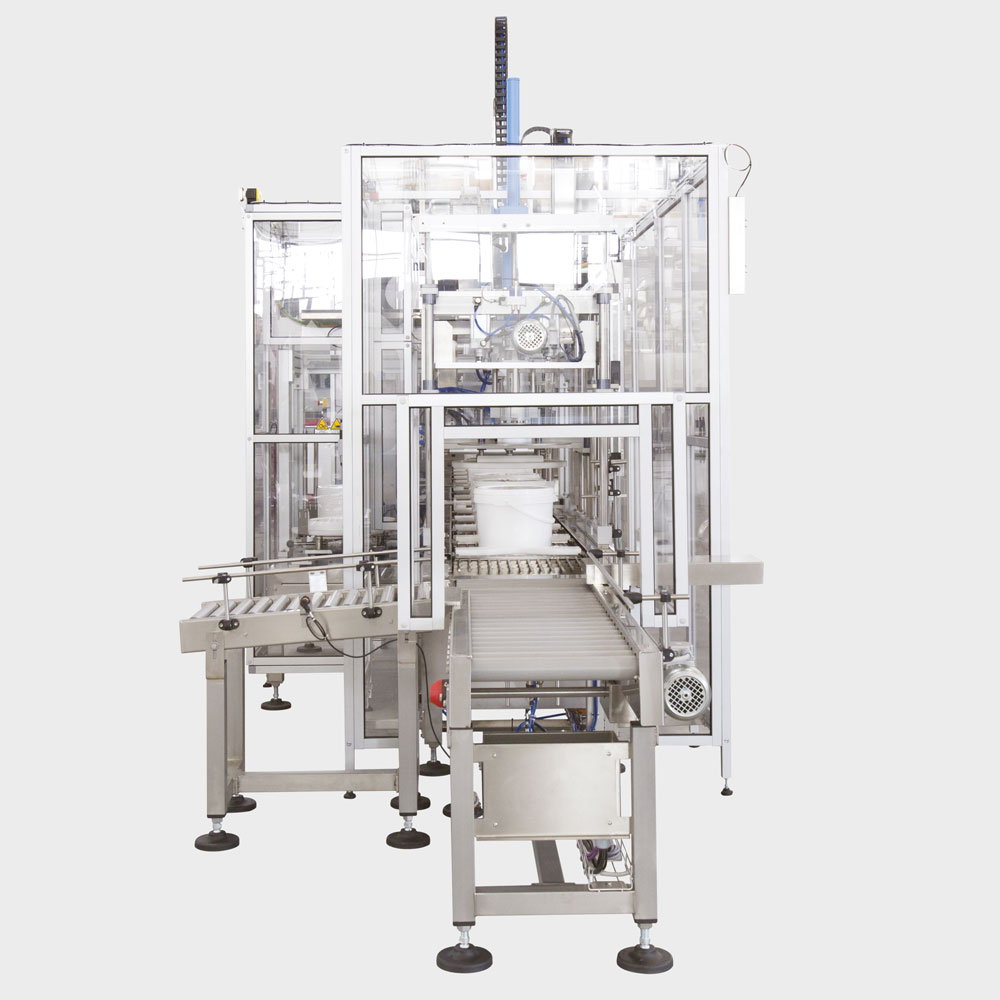

LRS

Linear step machine for unstacking, filling, sealing and capping plastic and metal buckets. Possibility of using format from 1 kg up to 25 kg of product with fast and automatic format changes. Suitable for filling with liquids, pastes and creams, food and non-food.

- Automatic denesting buckets by Cartesian axis driven by brushless servomotors, complete with buckets storage.

- Product dosage area with a weight load cell. Dosing head with drop saver.

- Thermosealing film from a reel.

- Automatic Capping buckets with stackable caps by Cartesian axis driven by brushless servomotors, complete with lids storage.

- Edging of metal covers.

Ecopackaging: the future

of packaging

The energy efficiency of the machine is guaranteed by the construction according to the EU regulation 2019/1781, through motors connected to inverters, in accordance with IEC 60034-30 standard on the efficiency classes of AC motors with mains power supply.

Paper film

Compostable materials

100% recyclable